ISRO accredited SMT Reflow facility

We are capable of producing both Aerospace type PCBs as well as general quality added type PCBs.

Machineries are as follows:

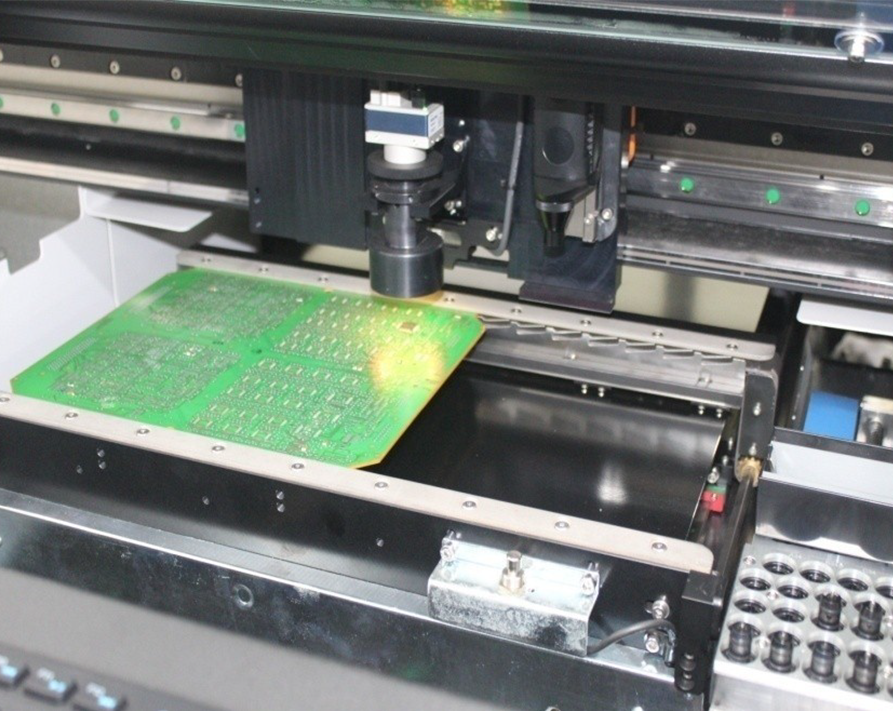

- Pick and Place Machine, Model: MY 300LX, Make: Mycronic, Sweden

- Reflow Oven, Model: JTR 800N, Make: Schenzhen JT Automation

- Stencil Printer, Model: E By DEK, Make: ASM Assembly Systems

- X-Ray Inspection facility, Model: X-Scope 1800, Make: Scienscope

- Solder Paste Mixer, Model: GAM 60, Make: Genetic Technology

- Fluid Dispensing Unit, Model: D260, Make: Axxon

- Dry Storage Cabinets, Model: A1B-600, Make: Dr Storage

SMT Reflow facility

In the SMT Reflow Facility, the following additional facilities are provided. They are :

- High Precision Inspection Facility

- Rework Facility

- Manual Fluid Dispensing Facility

- PCB Cleaning Facility

- Storage Facility

- Online 80KVA UPS for the facility, Make: Keltron

Pick and Place Machine - MY 300LX

Pick and Place Machine - MY 300LX

Stencil Printer – ASM E By DEK

Reflow Oven - JTR 800N

X-RAY INSPECTION – SCIENSCOPE

Features

- 4" x 3" digital flat panel detector

- 90 kV- 5 micron x ray tube

- Z axis movement of the x-ray tube

- Computer controlled kV and mA settings

- Computer controlled variable speed X-Y stage

- Full featured Image processing CPU with 23" LCD flat panel monitor

- 6" x 18" stage and 70 degree oblique angle viewing

- Mega pixel mapping camera with zoom window - easy location and identification of faults

- Programmable computer controlled - variable speed X-Y stage with a 70 degree sample tilt fixture

- Simple point and click inspection routines

Humidity Controlled Storage Facilities

- Capacity : 1400 Litres, Qty: 5 Nos.

- Capacity : 700 Litres, Qty: 2 Nos.

- Humidity Range : 1-60% RH

Solder Paste Mixer

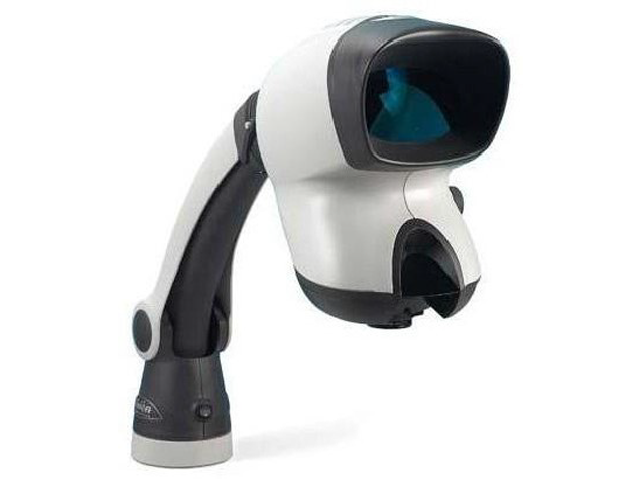

High Precision Inspection Facility

Features

- 2x, 4x, 6x, 8x, 10x magnification, quick change

- 3D Stereo viewing

- Long working distance and wide field of view

- Ergonomic eyepiece-less design

- Low operator fatigue, high productivity

- Bright white LED Illumination

Features

- Upto 40x zooming

- Continuous zoom effect

- Parfocal zoom objectives

- Binocular/ Tinocular head with C Mount Camera attachment facility

- Eye diopters adjustment of the viewer

- Facility of Full interface with PC through CMOS Camera

- Facility of Complete windows based measurement software

Bga Rework Station

PRO 660 Specifications

- PCB Size Minimum 8×8mm

- PCB Size Maximum Allowable 450×450mm

- PCB Size Recommended Max. 400×350mm

- PCB Thickness 0.5mm-6mm

- Component Size MAX 60*60mm MIN 2*2mm

- Minimum BGA Ball pitch 0.3mm

- Placement Precision ±0.02 mm

- Heating System

- IR Bottom-heater 400×350mm(4200W)

- Component heater Top

- Hot Air 800W

- Component heater Bottom

- Hot Air 1200W Temperature Control K-Type

- Thermocouple; Closed Loop

- PID Machine Specification

- Main Power Source Single phase AC220V 50/60Hz

- Total Power Consumption 6400W

- Machine Dimensions L1000×W880×H990mm

- Net Weight 105kg

Thermal Climatic Chamber (WEISS)

Specifications

- Capacity – 800 litres

- Temperature range – 72oC to 180o C Relative humidity- 10% to 98%

- Humidity Operating Temp Range-+10deg C to +95deg C Ramp rate up to 12 K/min

- Heat Compensation at -20deg C -8000Watts

- Heat Compensation at+20deg C -8000Watts

Specifications

- Peak Sine Force-3500Kgf

- Random Force RMS-3500Kgf

- Half Sine Peak Shock Force- 8400Kgf

- Shock Force-8400Kgf

- Usable Frequency Range – 3 to 3000 Hz

- Max. Acceleration – 110 g

- Max Velocity (Sine)-1.8m/Sec

- Max. Displacement – 51mm Pk. Pk Armature Weight- 33.2Kg Armature Diameter-440mm

- Fundamental Resonance Frequency of Armature-2650 Hz to 3000 Hz

- Slip table size – 1220 mmx1220mm, Square Type

- Head Expander Size- 762 mm x762 mm, Square Type

Clean Room Facility - Class 100000 (Performance 10000) For Satellite Jobs

- Class: 1 lakh class

- 238 Sq. mtr inside area

- Completely ESD protective (ESD audit completed)

- ESD monitoring wrist strap devices mounted on all tables for ESD real time monitoring.

- ESD footwear and wardrobe shelf

- ESD work table, ESD Mechanical table, ESD Testing table

- ESD Supervisory table, ESD Stores table

- ESD Conformal coating table,

- ESD Cleaning & tinning table

- ESD Chairs, ESD Bins, ESD shelves

- ESD portable drawyer, ESD footwear, coats, head cover, footwear cover etc.

Equipment Available For Satellite Production

- Hand held particle counter – Make VPC 300,EXtech

- Overhead ionizer- 5 Nos. (Make: Toki &Highstar technology)

- Table top ionizer- 15 Nos. (Make: Toki &Highstar technology)

- Ionic contamination tester- GEN3 systems CM33L+ Tank Size – 610 x 610 x 90 mm

- Humidity chamber 1400L (Make: Bosskey)

- Tower Hepa filters (Make :Mark air) – 4 Nos. class- 1 lakh (For converting existing area to cleanroom)

- Fluid dispenser system for conformal coating (Make: Fisnar)

- 230 LPM air compressor- Qty:1 (Make: mgf Prime)

- Deionizer gun- 1 No. (Make: Highstar technologies)

- Fume absorption unit- Make: Bosskey, Qty: 5 Nos.

- Microscopes, Fabrication tools, Magnification lenses, crimp tools, tweezers, vacuum pick up tools,

- Tinning pots- Qty-2 Nos. (Make: weller)

- Soldering stations- Weller Qty: 10 Nos.

- Thermal wire strippers- Make: StripalQty: 5 Nos.

- Hot air oven , Make: Thermosystem, 30-300 degrees size (1.2ft x 1.2 ft x 1.2 ft)

Clean Room Facility

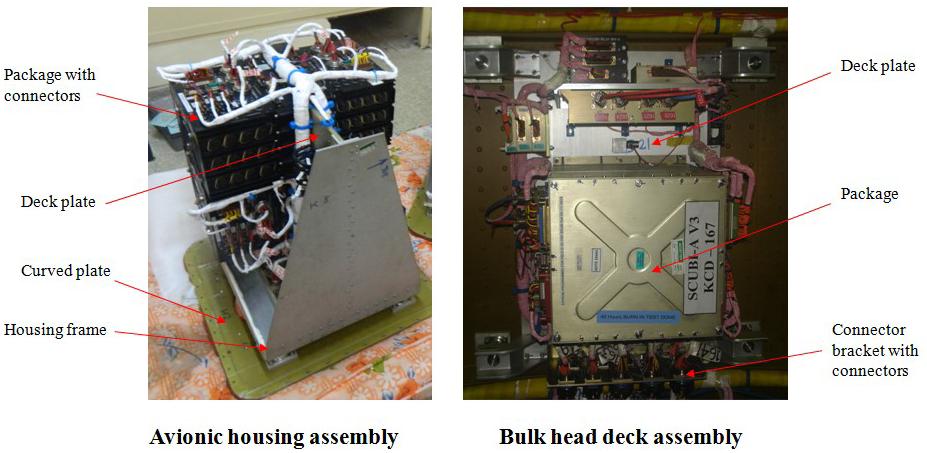

Test & Evaluation Works Of Flight Packages

PSLV/GSLV Packages

- SCOUT

- EB INST PSM o EB NGC PSM o PS3 FNC PSM

- PS2 INST PSM

- 1S ½ U IF UNIT

- BS NGC PSM/GSI NGC PSM

- BS TVC PSM

- BS INST PSM

- BS TVC/RCS PSM

- SARB A/B/C

- BS PPEX UNIT

- ALL EXT/SAFE IF U

- GPIU TYPE 1/11

- GIU GCP/SPM

- CE PSM

- DIODE BOX PS3 A

- VVM IF UNIT

- BS ATS PSM

- RBB 15 K, 2.2 K

- ISMU –V2

- SCUBI A & B

- GS2 NGC PSM

- GS2 IF U

- GS1 INST PSM o GS2 INST PSM o GIU SCOUT

- GIU REM/DSU

- GIU ALL EXT/SAFE

- CRYO SARB II o OPTICOM IFU o MOVIE

- RTD POWER I/F U

- GIU I/II

- SARU

- CRYO INHIBIT

- SBU FB/QB PS3A

- PYCM (I/II)

- CMM I to VII

- SSB

- EGC POWER CUT OFF UNIT

- L 40 NC PPEX

- SCOUT T/M (A/B)

- ½ L PPEX

- L 40 PEX M

- BS NGC PSM/ GS1 NGC PSM

- SARB III 1M,2M,3M,4M

- PS3 CE PSM

- BS ATS PSM

- OPTICOM IFU

- QUAD SBU (QB/ FB)

- LS AVIONICS PSM

- LS ACTUATOR PSM

- EMA PSM

- LVM3 EB INSTR PSM

- LVM3 EB NGC PSM

- LVM3 EB ACTUATOR PSM

Infrastructure For The T&E Center

- CLIMATIC CHAMBER

- DC POWER SUPPLIES

- DIGITAL & ANALOG MULTIMETERS

- CURVE TRACER, LCR METER

- IR METER, MEGGER

- FREQUENCY COUNTERS, OSCILLOSCOPES

- FUNCTION GENERATORS & OTHER ANALYSERS

- ASSEMBLY FIXTURES

- SCUBI CHECKOUT

- ISMU CHECKOUT

- DIGITAL MEMMORY RECORDER

- TEMP. CONTROLLED OVEN

Infrastructure For Production

- CRIMPING TOOLS

- LEAD BENDING TOOLS

- HAND PRESS, CABLE CUTTERS

- HOT AIR BLOWERS

- MAGNIFIERS

- DEAD WEIGHT CALIBRATOR

- VACUUM PUMP

- MICROSCOPE

- SOLDERING STATIONS

- TINNING POTS

- DEGOLDING POT

- LAMINAR FLOW TABLE

- ULTRA SONIC CLEANER

- DIGITAL PRESSUER CONTROLLER

- FUME EXTRACTORS

- WIRE STRIPPERS

- SMART TWEEZERS

- SURFACE PLATE

- DESICCATORS

- ENGRAVING MACHINE

- DRILLING MACHINE

- TORQUE SET

- VERNIER CALIPER AND MICRO METER

- VACCUM PUMP

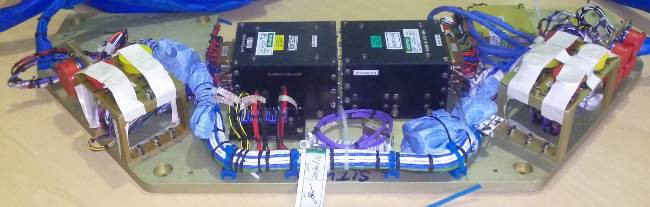

Harnessing work for PSLV /GSLV/MARK III

- EB+PS4

- ½L structure

- ½L Decks

- PS3 Adapter

- GSLV T/F Structure

- GSLV T/F Decks

- P ½ M

- S200 PP